Placement Heads: 8 Nozzles

Average Placement Rate:22,000-30,000CPH

Feeder Ports:88 NXT slots

Max applicable PCB:380mm*600mm

Support loose component feeder, strip feeder and IC tray feeder.

suitable for stable production of large production.

Weight:1500KG

Placement Heads: 8 Nozzles

Average Placement Rate:14,000-20,000CPH

Feeder Ports:52 (Front 26, Rear 38)

Max applicable PCB:380mm*600mm

Support auto nozzle changer 12-hole

Support loose component feeder, strip feeder and IC tray feeder.

suitable for stable production of medium to large production.

Placement Heads: 8 Nozzles

Average Placement Rate:14,000-20,000CPH

Feeder Ports:52 (Front 20, Rear 32)

Max applicable PCB:380mm*580mm

Support auto nozzle changer 6-hole

Support loose component feeder, strip feeder and IC tray feeder.

suitable for stable production of medium to large production.

Placement Heads: 6 Nozzles

Average Placement Rate:12,000-16,000CPH

Feeder Ports:58 (Front 24, Rear 34)

Max applicable PCB:380mm*580mm

Support auto nozzle changer 6-hole

Support loose component feeder, strip feeder and IC tray feeder.

suitable for stable production of medium to large production.

Placement Heads: 4 Nozzles

Average Placement Rate:7,500-11,000CPH

Feeder Ports:52 (Front 22, Rear 30)

Max applicable PCB:350mm*475mm

Support Automatic nozzle change 2-hole

Supports loose component feeder, strip feeder and IC tray feeder.

Suitable for high-precision PCB prototyping and small production.

Placement Heads: 4 Nozzles

Average Placement Rate:7,500-11,000CPH

Feeder Ports:52 (Front 22, Rear 30)

Max applicable PCB:350mm*475mm

Support Automatic nozzle change 2-hole

Supports loose component feeder, strip feeder and IC tray feeder.

Suitable for high-precision PCB prototyping and small production.

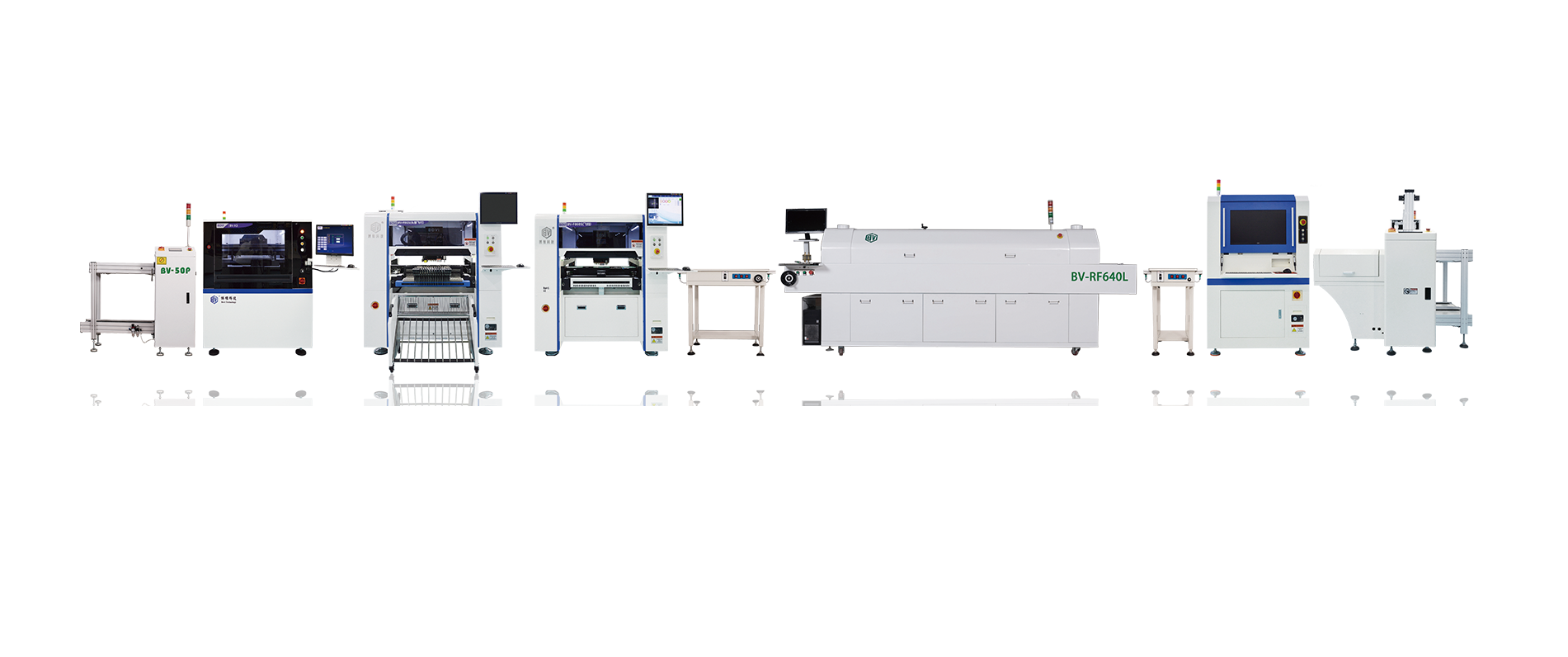

Bovi has established a close collaborative alliance with peripheral equipment suppliers, offering complete production lines and upstream/downstream supporting equipment services.For example Solder Paste Printer、Wave Soldering Machine、A0I、PCB Loader/Unloader、Reflow Oven、Solder Paste Mixer 、 SMT Conveyor. We provide customers with one-stop services, including on-site consultation, purchasing, and maintenance, striving to become the leading integrated production line provider in China’s electronics industry!

1. Acceptable Tank diameter:60-67 standard 2. Motor speed: 1350 PRM First revolution: 400 RPM, Second rotation: 300 RPM. 3. Time setting: 0.01s~99H99s, minute and second set 4. Dimension: 400x400x500mm(W*D*H) 5. Weight: 45KG Configure: 1.Voltage:AC220V.50/60Hz 2.Operational capacity: 0-1000g * 2 tanks

1. Max PCB Size: (50-250)mm*350mm(W*L) 2. Magazine Size: 355x320x563mm 3. Transport Height: 900±20mm 4. Control System: PLC+Touch Screen 5. Language: English 6. Signal Connection: SMEMA 7. Dimension: 1150x880x1250mm 8. Weight: 180KG Configure: 1. Voltage: AC220V,50/60Hz 2. Direction: Left to Right or Right to Left 3. Two Magazine For Free Auto Width Adjust

1. PCB Size: (50-250)mm*350mm(W*L) 2. Magazine Size: 355x320x563mm 3. Transpont Height: 900±20mm 4. Control System: PLC+Touch Screen 5. Language: English 7. Signal Connection: SMEMA 8. Dimension: 1700x1450x1200mm 9. Weight: 150KG Configure: 1. Voltage: AC220V.50/60Hz 2. Direction: Left to Right or Right to Left 3. Two Magazine For Free Auto Width Adjust

1. Max PCB Size: (50-250)mm*350mm(W*L) 2. Magazine Size: 355x320x563mm 3. Transport Height: 900±20mm 4. Control System: PLC+Touch Screen 5. Language: English 6. Signal Connection: SMEMA 7. Dimension: 1550x880x1250mm 8. Weight: 200KG Configure: 1. Voltage: AC220V,50/60Hz 2. Direction: Left to Right or Right to Left 3. Two Magazine For Free Auto Width Adjust

Inline AOI is integrated directly into the production line, enabling real-time inspection during the manufacturing process to quickly identify and correct defects. 1. Rail: Singal Rail 2. PCB Size: 35*35~340*400mm 3. Transfer Height:900±20mm 4. Camcra Pixels: 6million industrial camera(can customized) 5. Control Method:PC 6. Operation System: Microsoft Win7/ Win10 7. Language; English 8.Dimension: 1300*1000*1540mm 9.Weight: 700KG Configure: 1. Voltage:AC220V.50/60Hz 650W 2. Direction: Left to Right 3. FOV: 36 mm * 30 mm

Offline AOI operates as a standalone unit, where PCBs are manually loaded for inspection after production. 1. PCB Size: 25*25~340*450mm(can customized) 2. Minimum components:0201 3. Camcra Pixels: 6million industrial camera(can customized) 4. Control Method:PC 5. Operation System: Microsoft Win7/ Win10 6. Language: English 7. Dimension: 900*1100*1350mm 8. Weight: 480KG Configure: 1. Voltage:AC220V.50/60Hz 600W 2. Resolution Option:10μ

The wave soldering unloader is located behind the wave soldering machine, removing completed PCBs from the production line. 1. Max PCB Width: 350mm 2. Transpont Height:1400-780mm 3. Dimension: 1200x500x1350mm 4. Weight: 40KG Configure: 1. Voltage: AC220V.50/60Hz 60W 2. Direction: Left to Right or Right to Left

BOVI, as a leading SMT machine manufacturer, offers tailored SMT production line solutions and a range of other services to meet diverse customer needs.

The SMT production line typically includes components such as loaders/unloaders, stackers, solder paste mixers, stencil printers, high-speed chip mounters, conveyors, reflow ovens, automatic optical inspectors (AOI), and X-RAY detectors, all customizable to meet specific customer requirements. Various PCB assembly line configurations are available for flexible combination.

BOVI, a trusted SMT equipment supplier/manufacturer, offers an extensive selection of high-quality pick and place machines at prices that deliver exceptional value. Whether you’re looking to upgrade your existing equipment or establish a new production line, we’re here to help.

Bovi technology has established for over twenty years, is the leading supplier of SMT P&P machine and accessories in China with a commitment to provide the market with complete SMT assembly line solutions.Our company is headquartered in Jiaxing (Zhejiang Province), has set up branches and offices in Beijing, Jiangsu, Guangdong, Shenzhen, covering a total area of 10,000 square metres.

BOVI has always been committed to building mounter self-owned brand, provide intelligent SMT equipment solutions for the global electronic information industry!Following the business tenet:”QUALITY FIRST, SERVICE FIRST”, and try to provide global customers with Chinese automation equipment and solutions with excellent performance and unbeatable prices and unmatched After-Sales Support.

Copyright © BOVI Co., Ltd. All rights reserved.