- Home

- Reflow Oven

Reflow oven

The reflow oven is a welding facility in SMT production,which is used to solder SMT electronic components on the board. The reflow oven relies on the flow of hot air in the inner oven to melt the solder paste soldered on the circuit board into liquid tin, so that the SMT electronic components could be soldered together with the circuit board. Then, it is cooled by a reflow furnace to form a solder joint, and the gel-like solder paste is physically reacted under a specific high-temperature airflow to achieve the welding effect of the SMT process. It is a fully automated, high-precision method that ensures reliable electrical connections and mechanical bonding.

We offer various types of surface mount reflow ovens (e.g.,10 Upper/10 Lower Heating Zones,8 Upper/8 Lower Heating Zones , 6 Upper/6 Lower Heating Zones,4 Upper/4 Lower Heating Zones) to accommodate different thermal requirements.You can select the most suitable model based on your specific needs.

Types of Reflow Oven

Benchtop Three-Zone Reflow Oven

2. Heating Length: 1000mm

3.Control Method: touch screen control

4.Dimension: 1500×610×670mm

5.Weight: 120KG

Configure:

1.PCB Direction: L→ R

2.Voltage: 220V AC 1KW

4 Upper/4 Lower Heating Zones Reflow Oven (Mesh belt +Instrumentation control)

2. Heating Length: 1400mm

3. Transfer Height: 880±20mm

4. Conveyor Type: Mesh belt conveyor

5. Control Method: Instrumentation control(can customized)

6. Individual closed-loop control of each heating zome(± 1°C)

7. 4 Upper/4 Lower Heating Zones

8. 1 Cooling Zones

9.Dimension: 2500*612*1220mm

10.Weight: 300KG

Configure:

1.PCB Direction: L→ R, R→ L

2.Voltage: Three-Phase 380V AC 3KW

3.UPS (can customized)

4 Upper/4 Lower Heating Zones Reflow Oven (Chain-driven Rail-guided +Instrumentation control)

2. Heating Length: 1400mm

3. Transfer Height: 880±20mm

4. Conveyor Type: Chain-driven Rail-guided conveyor

5. Control Method: Instrumentation control(can customized)

6. Individual closed-loop control of each heating zome(± 1°C)

7. 4 Upper/4 Lower Heating Zones

8. 1 Cooling Zones

9.Dimension: 2500*612*1220mm

10.Weight: 320KG

Configure:

1.PCB Direction: L→ R, R→ L

2.Voltage: Three-Phase 380V AC 3KW

3.UPS (can customized)

6 Upper/6 Lower Heating Zones Reflow Oven (Mesh belt +Instrumentation control)

2. Heating Length: 2200mm

3. Transfer Height: 880±20mm

4. Conveyor Type: Mesh belt conveyor

5. Control Method: Instrumentation control(can customized)

6. Individual closed-loop control of each heating zome(± 1°C)

7. 6 Upper/6 Lower Heating Zones

8. 1 Cooling Zones

9.Dimension: 3500*700*1320mm

10.Weight: 400KG

Configure:

1.PCB Direction: L→ R, R→ L

2.Voltage: Three-Phase 380V AC 5KW

3.UPS (can customized)

6 Upper/6 Lower Heating Zones Reflow Oven (Chain-driven Rail-guided +Industrial PC)

1. Max PCB Width: 350mm(can customized)

2. Heating Length: 2200mm

3. Transfer Height: 880±20mm

4. Conveyor Type: Chain-driven Rail-guided conveyor

5. Control Method: Industrial PC+PLC

6. Individual closed-loop control of each heating zome(± 1°C)

7. 6 Upper/6 Lower Heating Zones

8. 1 Cooling Zones

9.Dimension: 3600*750*1320mm

10.Weight: 450KG

Configure:

1.PCB Direction: L→ R, R→ L

2.Voltage: Three-Phase 380V AC 5KW

3.UPS (can customized)

Deluxe 8 Upper/8 Lower Heating Zones Reflow Oven (Chain-driven Rail-guided +Industrial PC)

2. Heating Length: 3150mm

3. Transfer Height: 880±20mm

4. Conveyor Type: Chain-driven Rail-guided conveyor

5. Control Method: Industrial PC+PLC

6. Individual closed-loop control of each heating zome(± 1°C)

7. 8 Upper/8 Lower Heating Zones

8. 2 Cooling Zones

9. Dimension: 4600*1000*1420mm

10.Weight: 1100KG

Configure:

1.PCB Direction: L→ R, R→ L

2.Voltage: Three-Phase 380V AC 5KW

3.UPS (can customized)

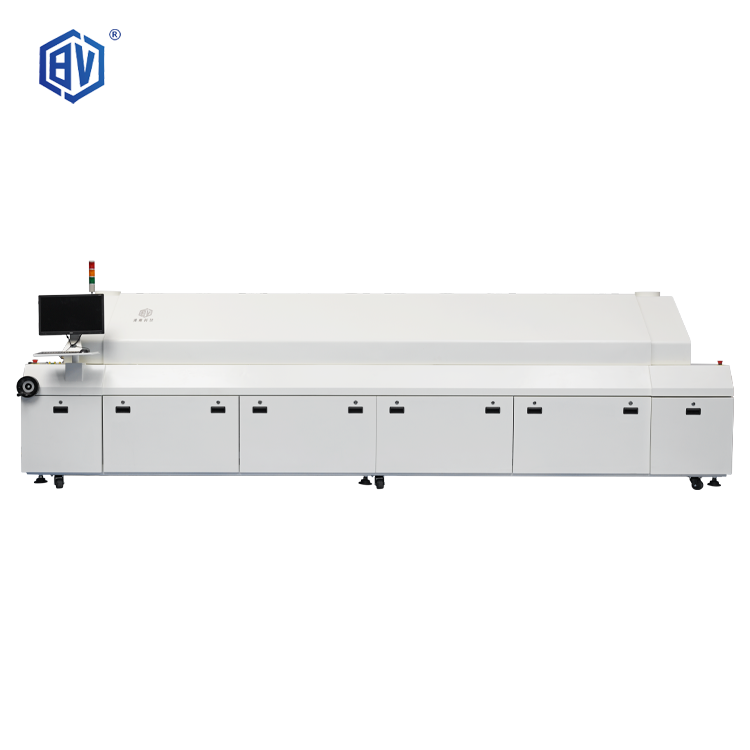

10 Upper/10 Lower Heating Zones Reflow Oven (Chain-driven Rail-guided +Industrial PC)

1. Max PCB Width: 450mm(can customized)

2. Heating Length: 3150mm

3. Transfer Height: 880±20mm

4. Conveyor Type: Chain-driven Rail-guided conveyor

5. Control Method: Industrial PC+PLC

6. Individual closed-loop control of each heating zome(± 1°C)

7. 10 Upper/10 Lower Heating Zones

8. 2 Cooling Zones

9. Dimension: 5000*1200*1520mm

10.Weight: 1200KG

Configure:

1.PCB Direction: L→ R, R→ L

2.Voltage: Three-Phase 380V AC 10KW

3.UPS (can customized)