Offline AOI operates as a standalone unit, where PCBs are manually loaded for inspection after production.

1. PCB Size: 25*25~340*450mm(can customized)

2. Minimum components:0201

3. Camcra Pixels: 6million industrial camera(can customized)

4. Control Method:PC

5. Operation System: Microsoft Win7/ Win10

6. Language: English

7. Dimension: 900*1100*1350mm

8. Weight: 480KG

Configure:

1. Voltage:AC220V.50/60Hz 600W

2. Resolution Option:10μ

| Model | BV-500 | |

| Discriminant method | Combining weighted imaging data difference analysis technology, color image contrast, color extraction analysis technology,similarity, binarization, OCR/OCV, pathway testing and other algorithms | |

| Camera | Hikvision robot 6 million CCD color industrial camera | |

| Light source | RGB ring LED structure light source, imported ROHS standard LED lamp | |

| Image processing speed | 0402 components | <6ms |

| One screen processing time | <100ms | |

| Testing content | Solder paste | Non-tin,misalignment,less or printing more tin,briding,pollution |

| Defects in parts | Components,skewing,misalignment Testing content,stele,side stand,turn over,polarity reverse,wrong component,damage | |

| Solder joint defect | less or more tin, tin-connection | |

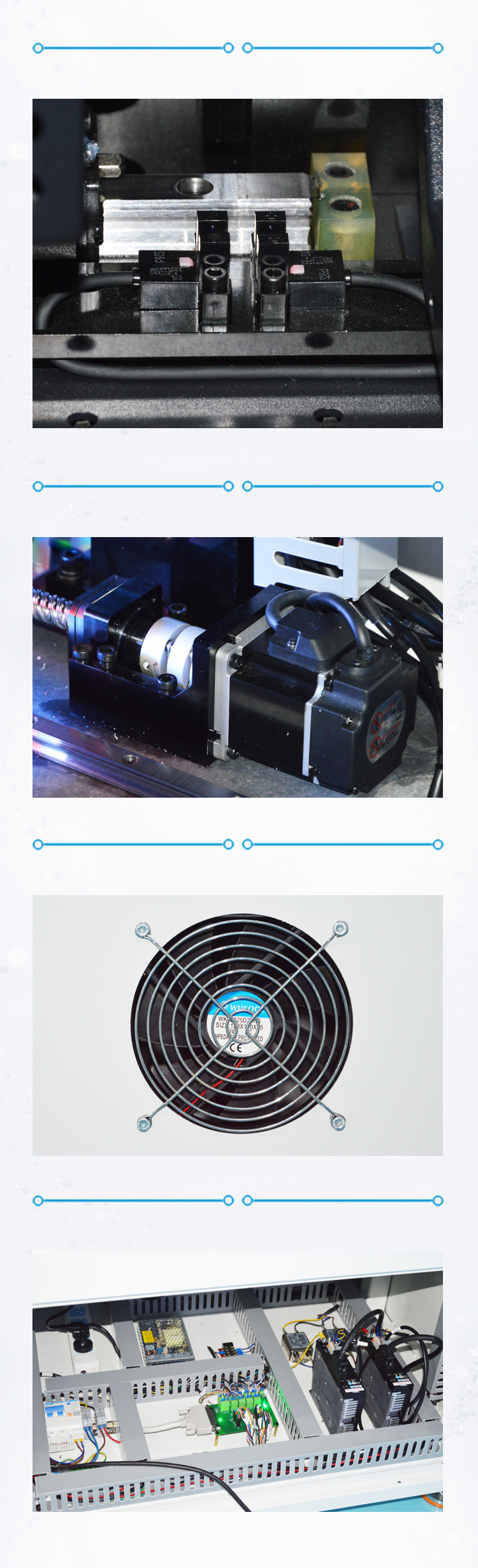

| X, Y platform | Drive device | High precision silent grinding screw rod and guide rail combination (Taiwan TBl and Japan’s (NIDEC) servo motor system |

| Positioning accuracy | <15um | |

| Moving speed | 750 mm/s | |

| Mark | Points | You can select two commonly used Mark points or multiple Mark points |

| Recognition speed | 0.5s/picture | |

| Display | 24 inch LCD widescreen Display (Philips) | |

| PC host | HS industrial host, CPUI7-4770,8G memory,512G SSD | |

| Dimension(L*W*H) | 870mm*950mm*1320mm | |

| Weight | About 450 kg | |

| Power supply | AC 220V± 10%,50/60Hz,rated power 600W | |

| Mechanical system | Anti-static measures | Antistatic socket,anti-static ring |

| PCB size | 25X25mm~340mmX450mm mm (larger size can be customized according to customer requirements) | |

| PCB thickness | 0.5mm~2.5mm | |

| PCB warp degrees | <2 mm (a fixture auxiliary rectify deformation)can eliminate PCB deformation effects (special requirements can be customized) | |

| Components height | Up high<35mm, down high<70mm(special requirements can be customized) | |

| Minimum components | 0201 components | |

Q:Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT production line, including SMT Pick and Place

Machine, Reflow Soldering Oven,Soldering Paste Printer, and other SMT production line assembly machines.

OEM &ODM service are available.Please feel free to let us know your requirements.

Q:Does your machines have quality certificate?

A:All of our machines have passed CE certificate,RoHS,ISO9001(IQNET)and have own more than 60 patents.

Q:English version for these machines?

A:Yes,and we will regularly update the software for customers.

Q:Is it hard to use these machines?

A:No, not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

Q:What’s the way of shipping?

A:These are all heavy machines; we suggest you use cargo ship. But components for mending the machines,

air transportation would be fine.

Q:How about the warranty?

A:We support one year warranty. We will regularly update the software for customers. If there is any doubt in

the process of operating the machine, pls feel free contact us. We will help you in time.

Q:How is the training?

A:After buying our machines, your engineers can go to our company.We have English user manual and guide

video to teach you how to use the machine .The user manual will come with the machine together.

Q: Why choose us?

A:Jiaxing Bovi Electronic Technology Co., Ltd. is reliable supplier for SMT pick and place machine&SMT

production line in China and overseas.We have more than 20 years professional R&D team, providing 24

hours quick response after-sales service.

Copyright © BOVI Co., Ltd. All rights reserved.