Wave soldering is an electronic manufacturing process used for batch soldering of through-hole components. The molten liquid solder forms a wave-like solder wave crest. When the PCB with inserted components passes through the solder wave at a specific angle, the solder comes into contact with the component leads and pads to complete the soldering process.

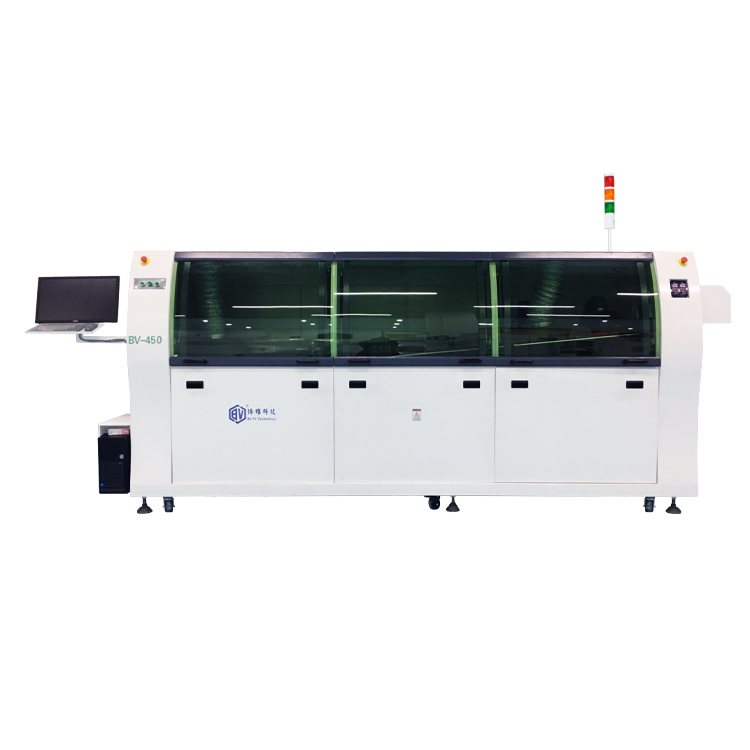

Bovi Tech’s self-developed dual-wave soldering machine consists of two parts: a smooth wave and a turbulent wave.

The turbulent wave serves as the first wave peak, performing preliminary soldering on SMD components. By rapidly moving the solder wave, it removes residual flux trapped in shadowed areas, providing reliable lubrication for solder joints. This wave is characterized by its high crest, ensuring sufficient solder coverage in shadowed regions.

The smooth wave acts as the second wave peak, primarily assisting in soldering to reduce defects such as solder spikes and insufficient solder, thereby improving soldering quality. With its gentle waveform, it helps reshape solder joints, separating bridges between pins and terminals while eliminating soldering defects. This ensures well-formed solder joints, preventing issues like bridging, icicles, and cold solder joints.

Copyright © BOVI Co., Ltd. All rights reserved.